A Make It Yourself Hive Loader

By: Jerry Bromenshenk

Large scale beekeepers often place hives on pallets and move them using forklifts and flatbed trucks.

Small scale beekeepers are more likely to have a pickup truck or trailer. The problem is loading and unloading hives, especially if one is working alone.

A bed-mounted hoist is really handy but most are expensive. It’s time to make a trip to a discount tool store like Harbor Freight (HF) or Northern Tool. I’ve got a nearby Harbor Freight store. A hydraulic-jack ½ ton hoist with a hand-crank winch costs $89 for a short crane and $149 for a taller crane. For another $89, you can toss the hand-winch and replace it with an electric ATV winch with a wireless remote control. Now you can operate the winch while steadying the hive.

If you don’t mind bolting everything into the bed of the truck or trailer, you’re ready to go. Just be sure to add a reinforcing plate to the truck bed, the thin bed sheet metal won’t take the strain. If your truck has a trailer hitch, spend another $18 for a 12” receiver hitch extender. Weld the base plate of the hoist to the extension, and you’ve got a crane that can be easily mounted and dismounted. If you or a friend can weld, that’s a total of $256 for the taller lift. Cost will be a bit more if you need to pay someone to attach the base onto the extension.

This works very well, but the downside is that since the crane is in the middle of the truck. You will have to either remove the tailgate or lift the hives up and over the sides of the truck. A better solution is to move the hoist to the side of the truck so that the tailgate can be opened. You can find this type of crane on the web in aluminum or steel for around $1500 plus shipping – ouch!

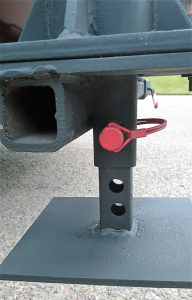

Not to worry, a chunk of square tubing welded into a T solves the problem. The hoist base needs support for heavy lifting, so you should add an adjustable foot. My design allows me to mount the crane on either side of any pickup with a trailer hitch. Basically, I had a T-shaped extension built, then added a longer, horizontal, square pipe that can be slid left or right to fit the truck, and a foot that slides up and down inside the vertical mast for the crane.

This part takes the most fabrication work. You need to drill a hole through the center of the crane base and weld on a piece of square tubing to receive the leg of the foot plate. None of the dimensions are critical, just fit to the base of the crane that you purchase and use the right-sized extension for the hitch on your truck. If you want to be able to adjust the left or right length or the height of the foot for uneven terrain, you’ll need to drill some holes – how many is up to you. Given that you are drilling two layers of rather thick-walled square tubing; I highly recommend a drill press.

The version of this crane that I use on my own truck has one more feature. I added a direct-wired controller to the electric winch. The wireless fob is easily to drop and lose in the grass, the battery may die, and there’s a bit of lag between pressing an up or down button and winch response. The crane-mounted controller is more precise, can’t be lost, and runs off the battery.

A few tips – the HF hand-crank winch has soft teeth and the cable may jam when spooling. If you use the HF winch, take up cable slack without any load, then use the jack to lift the load. If you lift the weight of a heavy hive by cranking the winch, it will self-destruct in a season or two. Leave the hydraulic jack in the down-position when not using. The jack shaft is prone to rusting if exposed to weather. Hook a loop of string through the keyhole in the remote control for the winch and hook to your belt or wear around your neck (just be sure that the string will break before it chokes you, if you hook it on something). HF’s crane has a loop for the jack handle pipe at the base of the crane.

I worry about bouncing the jack handle out on rough roads, or someone using it to smash a window to steal things from the cab or maybe even the truck. I carry the steel jack handle under a seat and have a light-weight handle that I leave in the base of the crane. I made it from a piece of PVC pipe with a wooden towel glued inside to take the flex out of the PVC. Light, cheap to replace, and it’s likely to take a lot of work to break a window with a PVC pipe.

I worry about bouncing the jack handle out on rough roads, or someone using it to smash a window to steal things from the cab or maybe even the truck. I carry the steel jack handle under a seat and have a light-weight handle that I leave in the base of the crane. I made it from a piece of PVC pipe with a wooden towel glued inside to take the flex out of the PVC. Light, cheap to replace, and it’s likely to take a lot of work to break a window with a PVC pipe.

The crane swivels, just remember to lock it down when driving or you may lose the rear window as the boom swings inward. Also, collapse the boom to its shortest length so it can’t reach the window.

There’s a locking pin for the crane swivel near the top of the mast. I replaced the HF clip with a bolt and a large thumb nut, painted red so I can easily find it. There’s also a grease-fitting near the top of the mast. Keep the mast well lubed; do so frequently or the mast will be hard to turn with a load on the crane. Don’t forget to raise the support foot before driving off! Otherwise you’ll dig a trench in the dirt or hear a scraping sound. Worst case, you hook a stump or curb and tear the whole thing off.

There’s a locking pin for the crane swivel near the top of the mast. I replaced the HF clip with a bolt and a large thumb nut, painted red so I can easily find it. There’s also a grease-fitting near the top of the mast. Keep the mast well lubed; do so frequently or the mast will be hard to turn with a load on the crane. Don’t forget to raise the support foot before driving off! Otherwise you’ll dig a trench in the dirt or hear a scraping sound. Worst case, you hook a stump or curb and tear the whole thing off.

The one change I’d make if I did this over would be to bend up the front of the support foot so it would act more like a sled, and I’d round the corners of the crane base – it’d be easier on the shins. Finally, the whole thing bounces and rattles if left loose. Before driving, I attach the crane hook to a bed tie-down, then tighten the crane until the cable pulls tight and starts to lift the whole assembly. That lifts the support foot even higher off the ground, and it keeps the crane assembly secure and stable with little or no rattles.

As per lifting hives, I have ratchet-straps on all of my research hives. We

slide the web strap through a D-ring, ratchet the strap tight, and attach the cable hook to the D-ring. That’s the cheapest and simplest solution. There are lots of slings for lifting hives that you can build or buy. Most either have a cradle the slips under the base of a hive or have clamping arms that use the handholds of a hive body. However, that’s added expense and one more thing to carry.

Jerry Bromenshenk is a Class Development Leader at the University of Montana’s, Master Beekeeper Programs and retired Researcher in the Entomology Department there. He is a frequent contributor to Bee Culture.