By: Bob Binnie

The debate on what constitutes good food seems to be endless.

Diets abound with notions that are as varied as the people expounding their virtues. This has put honey on some food hit lists being described as “just another sugar.” Nothing could be further from the truth.

Along with its antibacterial and antifungal properties, honey has been shown in multiple scientific and medical studies to have numerous health benefits. Honey contains over 180 substances, some of which allow our bodies to use it very differently than other carbohydrates. It is not “just another sugar.”

How good honey is for us, or whether it is any good at all, not only depends on how we use it, but also on how we process and store it.

This article will explore some of the chemistry of honey and how it can be affected by temperature, moisture, filtration and more. There are many pros and cons in honey processing, and knowledge of what we are dealing with can help us do a better job.

Temperature and Its Effect on Honey

For better or for worse, heat is often used in honey processing

Most operations handling more than a few buckets usually use heat in one form or another, even if it simply means warming honey to facilitate bottling. We should, however, be mindful that heat degrades honey and has an effect on many things including enzymes, color, flavor, and aroma.

Enzymes

Enzymes are important and all are affected by temperature. Merriam-Webster defines enzymes as complex proteins, produced by living cells, that catalyze or increase the rate of biochemical reactions. Simplistically put, enzymes can be thought of as energy. The presence of active enzymes is a part of what defines food that is alive and enzyme activity must be present in honey labeled “Raw.”

Let’s take a look at three notable enzymes in honey.

- Invertase converts sucrose in nectar to glucose and fructose, which helps make nectar able to hold more solids thereby making it more stable.

- Glucose Oxidase creates a chemical reaction which, among other things, lowers the pH of honey to an average of 3.9 and produces hydrogen peroxide. Both of these help stabilize nectar while ripening and contribute to the antibacterial properties of honey.

- Diastase, as with all enzymes, is destroyed by heat, and because its activity is easily measured, it has been used by some importers and packers to tell how much heat honey has been exposed to.

“Honey absorbs moisture in a high humidity environment.”

The effects of heat on an enzyme are commonly measured by the time it takes to reduce half of the enzyme’s activity or its “half-life” at a given temperature. For instance, the half-life of diastase in honey is 1,000 days at 68˚F, 14 days at 122˚F, and 30 seconds at 176˚F. The other enzymes in honey are affected similarly. Enzyme activity stops when honey is held at freezing temperatures but returns when warmed back up. It does not return when destroyed by heat.

Two interesting side notes are that almost all the enzymes in honey are introduced by the bees, and all break down when liquefying crystallized honey in a microwave.

Flavor, Aroma and Color

Although the chemistry behind flavor and aroma is complex and not very well understood, they are a part of what defines high quality honey, and care should be taken not to cause unnecessary deterioration. One thing we know for sure is that they, along with color, are sensitive to high temperatures and deteriorate with time.

For instance, the color of honey is very slow to change when stored cold, but as it warms back up, the rate that honey darkens (and it will darken), will triple with every increase of 10˚F. Flavor and aroma deteriorate in a similar fashion when temperatures rise. Something as simple as prolonged warming in a bottling tank, a hot warehouse, or even a hot spot in your kitchen will have a degrading effect on honey.

Flavor, aroma, and color are especially affected in honey that is heated while containing debris such as dead bees, old comb containing cocoons, hive trash, and much of the menagerie of things that can come out of an extractor.

Some go so far as to say that honey processed with any heat at all can no longer be called raw. We might be careful not to rush to judgement here, however. This could turn into a debate with Mother Nature considering the fact that the top tiers of a beehive, in full sun, on a hot summer day, can get quite warm. I submit that care and moderation are the key for those that want to produce a good, wholesome product.

National Geographic has recently reported that honey found in an ancient tomb in Egypt was still edible, but I’m not sure I would want to be the one to eat it. Just because it hasn’t spoiled (fermented), and is still edible, doesn’t mean it’s still good food. Although not all honeys will deteriorate at the same rate, all eventually do. As with many foods, fresh is best and time is not your friend.

On another note, the internet has more than a few articles written by celebrated food experts stating that it is harmful to put honey in the refrigerator. This is not true. Cold honey degrades slower than warm honey and freezing temperatures are actually your best defense against deterioration.

Materials in Processing

Honey reacts with most metals

Because of its acidity, honey reacts with steel, iron, aluminum, galvanized metal, copper, tin, and more. Besides producing toxins, this can also affect taste and color. Although some are worse than others, steel and iron are considered especially bad for honey storage because they can rust and ruin honey. At least two exceptions to all this are silver and gold, but because we will probably not be manufacturing storage tanks out of silver or gold any time soon, I recommend food grade stainless steel as the next best, practical choice.

When using plastic in honey processing and storage, only food grade will do because other plastics can release excessive toxins. When bottling with plastic, polyethylene terephthalate (say that three times fast), better known as PETE plastic, is considered one of the best choices. PETE is clear and can be identified as having a number 1 in the triangle on the bottom of the container. High-density polyethylene, also known as HDPE plastic, is also commonly used and can be identified with a number two in the triangle.

In my opinion, glass is better than plastic for food, or anything else we ingest, but because plastic will almost always outsell glass when sitting side by side in a grocery store it’s hard not to offer it. We offer both and let the customer decide.

Moisture

Too much moisture in honey lowers quality

Although moisture may not be a big issue in arid areas like the southwest, it can be in high humidity, higher rainfall areas such as the east and southeast. Having a high moisture content in honey lowers quality and leads to fermentation. It’s actually easy to affect the moisture level in honey. It all revolves around a few basic facts.

Honey is hygroscopic, which means it will absorb moisture from a high humidity environment. It’s also hydrophilic, which means it will release moisture when there is low humidity. There is always a point where the moisture level in honey will balance out with the humidity level it is exposed to and that honey will cease to gain or lose water. For example, given enough time, honey that is exposed to air with a 60% humidity level will balance out with it at about 18.3% moisture content. This is not a bad place to be. Most honey will not ferment at this level although there are some that will. When exposed to 50% humidity, the moisture content in honey will lower to about 15.9%. This is a better place to be because no honey will ferment at this level and because it will have a thicker body, more character, and richer flavor, it would be considered a higher quality product. When continually exposed to 80% humidity, the moisture content in honey will eventually rise to 33.1%. No, that’s not a typo. Unless pasteurized, honey with a moisture content that high will create enough pressure from fermentation to bend a metal jar lid into a dome if the seal holds or create a heck of a mess from leakage or both.

Honey bees try to keep their hive between 50% and 60% humidity for good reason.

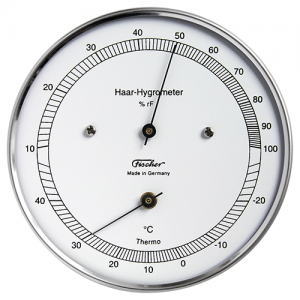

Transporting, storing, uncapping, extracting, and the general handling of honey in a high humidity environment will absolutely add moisture to your honey. Doing the same in low humidity will have the opposite effect. A high quality hygrometer, which measures humidity, can be a good thing to have in a honey house. Cheap humidity gauges are usually inaccurate.

If you need to remove moisture from honey, it’s helpful to understand that honey has a very poor diffusion rate. If, for example, you were to use a fan to blow warm air across the top of a drum of thin honey only the top layer would dry because the effect will not migrate very far.

For most of us, unless you have a commercial honey dryer, it’s best to remove moisture before extracting. Honey supers can be placed in a warm, low humidity drying room which allows for a much greater surface area to be affected by warm, dry, moving air.

When removing moisture it is helpful to know that by simply raising the temperature in a given space, the relative humidity level will drop thereby increasing the drying effect.

If this is puzzling, remember that relative humidity is the amount of water vapor the air is holding compared to what it could hold if totally saturated at 100%. By increasing the temperature the amount of water vapor air can hold increases, so the relative humidity level, or current saturation level, goes down. This, along with the use of a dehumidifier and fans, can create a good, dry, low humidity environment for drying honey. Also, warm honey is easier to extract.

If this is puzzling, remember that relative humidity is the amount of water vapor the air is holding compared to what it could hold if totally saturated at 100%. By increasing the temperature the amount of water vapor air can hold increases, so the relative humidity level, or current saturation level, goes down. This, along with the use of a dehumidifier and fans, can create a good, dry, low humidity environment for drying honey. Also, warm honey is easier to extract.

In our drying room at Blue Ridge Honey Co. we use two commercial dehumidifiers that run 24/7 during extracting season. Along with keeping the temperature 85 to 90˚F, this keeps the humidity level well below 30% even when it is as high as 100% outside. We move this air through the stacks of supers with industrial fans mounted on the ceiling and by doing so see a notable decrease in moisture content in just a few days. Although, contrary to popular belief, moisture can and does migrate through wax cappings, we try to harvest our honey supers with a small amount of comb still uncapped to achieve a quicker and greater overall moisture reduction. If you don’t have a refractometer for measuring moisture in honey you should get one. You may be surprised by what you find.

Yeast and Fermentation

Yeast can cause fermentation in high moisture honey

The yeasts found in honey are not the same as those used in bread and beer. They are tolerant of the high sugar concentration found in honey. The primary sources for these yeasts are flowers and soil and the bees bring it in freely.

Some bee books will tell you that fermentation will only occur in honey with a moisture content of 18.6% or higher. This is not always true. This number of 18.6% is dependent on the yeast spore count.

The yeast spore count in honey can range anywhere from one to tens of thousands per gram. Honey with a low spore count of one per gram will usually not ferment with a moisture content of up to 19%. Honey with a spore count of ten per gram needs to be 18.6% moisture or lower to be safe. A high spore count of 1,000 or more needs to have 17% moisture or lower, or fermentation can occur. For example, Mangrove honey with its low spore count is usually safe at 19% while Cabbage Palm honey with a higher than average count can sometimes ferment at 18%.

I can’t say how many times I have been surprised to have a barrel of honey that I thought was safe begin to show signs of fermentation. In my view, any hint of fermentation lowers the quality of honey and a high level completely ruins it.

Yeast is affected by temperature

Heat kills yeast and cold stops its activity.

One of the reasons some packers like to use heat in processing is that it stops fermentation in thin honey by killing the yeast. The yeast in honey will be dead in 8 hours when held at 125˚F, 30 minutes at 145˚F, and 1 minute at 160˚F. 100˚F or greater will slow fermentation, but honey stored for any time at these temperatures will show a noticeable deterioration of quality in other areas.

Be warned: if you think that killing the yeast in thin honey with heat will solve all of your fermentation problems going forward, think again. Yeast is everywhere. It is in your apiary, it is in your equipment, and it is airborne in your honey house.

“Producing a good quality product can be a challenge.”

Only if you heat honey in a sealed container or pour it hot into a container that will be sealed before it cools, will it be completely safe from fermentation. As soon as the container is opened again, if it is too thin, it is at risk. Again, yeast is everywhere.

If you do have to store thin honey and don’t want to use heat to kill the yeast, it can be stored cold. The activity of yeast in honey will stop when the temperature drops below 52˚F, but it will return when the temperature rises again.

Also worth knowing is that crystallized honey has a greater chance of fermenting than liquid. Not all of the sugars in honey will crystallize and the one that does (dextrose) has a lower solubility than the others. As it crystallizes, it will leave water behind thereby increasing the moisture content in the rest of the honey.

Numerous times I have had honey with borderline moisture content remain unfermented for some time only to have it ferment after crystallizing.

Why Crystallization Occurs

Crystallization will occur in honey with a moderate to high percentage of dextrose

A 20% content of dextrose, also known as D-glucose, in honey is considered low and 40% is considered high. Honey with a 25% dextrose content or lower will generally not crystallize. Fresh honey containing 40% or more will begin the crystallization process faster than you can read this article.

I was once extracting a crop of Canola honey (which is high in dextrose) only to come back after a weekend off and find it setting up in the sump tank, pumps, and pipes. If you’re not paying attention, honey like this can quickly crystallize in the comb and become almost impossible to extract. I learned this one the hard way.

Honeys high in dextrose will crystallize hard, and those with a moderate percentage will crystallize soft. A little lower percentage may give you a slurry or a thick, cloudy body.

Age can also have an effect on the consistency of crystallized honey. Over time, the percentage of dextrose in crystallized honey can decrease as it slowly converts to other sugars. This can give the appearance of honey that seems to have separated liquid from solid, with the solid on the bottom. Given enough time, some crystallized honey can actually go almost completely liquid again. Of course, this honey would be quite old and undesirable in my view because it will have deteriorated in other ways.

Examples of honeys low in dextrose are Black Sage, Tupelo, and Sourwood. Titi, Cotton, and Canola are honeys high in dextrose and because of this are sometimes considered bakers grade or industrial grade.

Crystallization is affected by temperature

The optimum temperature for crystallization is around 57˚F. Those producing creamed honey can use this fact to their advantage. The farther the temperature moves either above or below this range, the less apt honey will be to crystallize. Honey will not crystallize at or below 32˚F. Honey that has already crystallized will begin to soften at 85˚F and begin to liquify between 100˚F and 104˚F.

Heat is used to dissolve crystals in fresh honey that can initiate the crystallization process. Heat is also used to facilitate micro filtering which can remove particles that act as a platform from which the crystallization process can begin. Even a particle of dust can act as a starting point. Thirty minutes at 145˚F will dissolve all crystals.

If you need a long shelf life without crystallization, heat will probably be needed.

Filtration

A filter with an 800 to 1000 micron mesh can remove large debris while allowing desirable substances through.

Filtration is considered a sin by some, and absolutely necessary by others

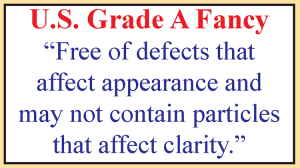

Honey labeled U.S. Grade A Fancy must be “free of defects that affect appearance and may not contain particles that affect clarity.” Although this standard for honey is not very well policed and can be highly misleading (much foreign honey is labeled US Grade A Fancy), many packers believe it adds consumer trust. Other than complying with this standard, there are other reasons many may not want particles in their honey. Besides crystallization and perceived shelf life issues, honey without particles can simply appear cleaner, brighter, and more attractive to consumers.

Of course, all of this requires fine filtering or “micro filtering” and there are those that feel this removes much of the “good stuff” in honey. That would include pollen, beeswax, and propolis particles, along with other substances considered desirable. Fine filtering also requires high heat to lower the viscosity (thickness) of honey so it can pass through a fine filtering medium. Honey handled like this should not be called raw although it often is.

The extreme opposite is honey sold as ultra raw. This honey is bottled straight out of the extractor, without any straining or settling at all and of course would contain a lot of foreign debris. While some would argue that the debris in freshly extracted honey is perfectly fine, even desirable, it’s important to keep in mind that not all debris is created equal. A bee wing or bee leg is one thing. A splinter or frame nail is quite another.

Just because I have product liability insurance doesn’t mean I want to use it. Some straining or settling is recommended. If you want to remove large, potentially harmful debris but allow much of the “good stuff” to remain, straining your honey through something like a coarse, 800 or 1000 micron filter will work.

Settling can also be helpful. Because honey is so heavy, light debris such as dead bees, wood, and wax will float to the top while heavy items such as nails, dirt, and wire will sink to the bottom.

To put filter mesh size in perspective most pollen particles run between 10 and 50 microns with one occasionally up to 100. In case you’re wondering, a micron, also known as a micrometer, is .001mm. or .000039 inch. The human eye generally cannot see a particle under 30 microns and a human hair is around 75.

Finally, on a personal note

I admit that when it comes to processing honey, producing a good quality product can sometimes be challenging. There will be mistakes made, and lessons learned the hard way. You may have to compete with people that have no problem with mislabeling and misleading customers. Let your quality and service speak for itself and remember it can take years to earn a good reputation, but it only takes a few seconds to lose it.

Bob Binnie is a commercial honey producer, honey packer and owns and operates Blue Ridge Honey Co. in Lakemont, Georgia along with his wife Suzette.