By: Marcel Durieux

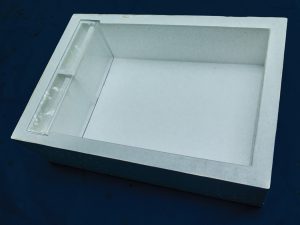

A BeeMax polystyrene hivetop feeder.

One of the charms of the top-bar hive (TBH) is its lack of standardization. It comes in a variety of forms, and everyone is welcome to create his or her own variant – which indeed is what many TBH builders do. But since there is no standard, it is difficult to find TBH accessories. This is particularly problematic in the area of feeders, for several reasons. First, in modern beekeeping, the feeder is really no longer an accessory: it is an essential. So you’ll need one. Second, the typical feeder models used with Langstroth hives are not easily adapted to the TBH. Entrance feeders don’t do well with entrances that consist of a row of holes, frame feeders don’t work well if in a hive that doesn’t use frames. A hivetop feeder needs the bees to be able to climb up between the top-bars, and that’s exactly what we don’t want in a TBH.

The bottom of the feeder, with the bee entrance, and showing the two seal bars – short pieces of wood glued next to the entrance to prevent bees from escaping once the feeder is placed on the TBH.

Most people therefore feed in-hive, with some device placed behind the colony, near the back of the hive. I myself have used entrance feeders placed inside the hive. Wyatt Mangum uses cut-off plastic trashcans, if needed strengthened by a piece of coat hanger wire. I trust this works well. In fact, I trust anything to work well that Mangum uses himself, since, with the number of TBH he manages, he certainly would not be using it otherwise. Others have created a feeding reservoir behind a divider board with an opening in the board for the bees to come through. The main problem with all these approaches is that the status of the feeder can’t be checked, nor the feeder refilled, without opening the hive. Various ingenious contraptions have been suggested that can be mounted on the back or front of a TBH. Again, Wangum describes several models in his excellent book “Top-bar Hive Beekeeping”(1). Here the problems include a fairly complicated construction, and a weight issue: if the capacity becomes too high, the feeder might tip the hive. Two gallons seems the maximum for the end, but Mangum suggests more might be possible if a feeder were mounted on the side of the hive.

A feeder on a TBH.

Here I’d like to describe a simple modification of a Langstroth hivetop feeder that allows it to be used on top of almost any TBH, accessible by the bees and by the beekeeper without opening the hive. The idea is to remove one top-bar, one not used by the bees and somewhere near the back of the hive, and to place the bee entrance of the feeder exactly over that hole. Any exits to the side need to be sealed, so that the bees can’t escape.

I use BeeMax polystyrene hivetop feeders. They’re easy to handle, hold three gallons of feed and require no maintenance (don’t forget to paint the outside prior to first use). But most importantly, they have their bee entrance near the end of the feeder, instead of in the center as it tends to be in many hivetop feeders. This allows me to use the last or next to last top-bar location as the feeder entrance, and this is helpful if the hive is occupied by a large colony that has taken possession of most top-bars. A feeder having its bee entrance in the center would overhang the end of the hive if I did this, and possibly tip. The modification consists of two short pieces of top-bar glued to the feeder as “seal bars” (I did say it was very simple…), one on each side of the bee entrance slit, and spaced such that the distance between their ends is the length of a top-bar. The two pieces plus the gap in between will together replace the one top-bar that will be removed from the hive.

The “topbar” on the far right is actually a divider board that closes the hive. The next “topbar” to its left is actually the seal bar glued to the feeder (made from an old topbar: note how the groove for the starter strip is pointing up instead of down). the next topbar to the left is an actual topbar. Also note the telescoping cover on the feeder, and the plastic sheeting drawn beneath it for rain protection.

To give some numbers: the bee entrance on a BeeMax feeder is 11.5“ (29 cm) wide. I use 18” (46 cm) top-bars on my TBH, and cut top-bar pieces 3” (7.5 cm) long for making the feeder seal bars. I glue them on leaving a distance of 12” (30.5 cm) in between, which will leave the bee entrance completely uncovered, and make the distance between the ends of the pieces equal to 18” (46 cm).

The sole purpose of these pieces is act as bee seals. They are not weight bearing, and therefore do not need specifically strong glue – I just use wood glue and let it dry for 12 h before using. If a wooden feeder is used, they could be screwed or nail on. One secondary benefit of the seal bars is that when the feeder is taken off the hive for maintenance and put on a flat surface, the bars will keep the bee entrance lifted off the ground. This prevents bees from being crushed, and allows bees still inside the feeder to get out and return to the hive.

Two feeders on a single, divided hive. The hive contains two small colonies, separated by a divider board in the center (the darker, narrow strip of wood visible between the feeders). The feeder seal bars 9third bars in from the divider) can be recognized as they don’t have starter strip grooves.

Before putting the feeder on the TBH, there are two more issues to deal with. First, the feeder top must be closed to prevent access by bees and other insects. The simplest solution is to get a standard Langstroth hive cover and use that. After all, that’s how it is designed to be covered. However, this becomes pretty expensive pretty fast. I use very a simple home-built telescoping cover made out of painted plywood, but undoubtedly other solutions would work. Even a sheet of plastic might suffice. One possibility to consider is the placement of a small observation window in the cover, so that both the feeder content and the bees taking it can be checked without even removing the cover.

Second, the TBH cover can’t be on the hive while the feeder is there, so any portions of hive not covered by the feeder need to be protected against rain. I do use plastic sheeting for this. In addition, I do put the hive roof on top of the feeder, for extra protection. But I use a very simple and light hive roof made out of corrugated plastic, and this approach may not work with some more complex roof designs.

It is of course not necessary to place the bee entrance of the feeder at the very end of the hive; it can be placed as close to the colony as one wishes, and it also can be moved when needed. However, the system will not work when bees can’t leave the cluster, such as during cold spells, or for feeding after hiving a package, when the food needs to be as close to the bees as possible. In that case, some in-hive feeder will work better.

It is possible to use two feeders on a single split TBH holding two smaller colonies!

References

Mangum WA: Top-Bar Hive Beekeeping: Wisdom & Pleasure Combined. Stinging Drone Publications, Bowling Green, VA. Pages 384-390