Electric Honey Extractor vs Manual Honey Extractor

Is an electric or manual honey extractor better?

Honey extractors make short work of separating the golden effort of bees — honey — from the intricate wax comb that houses it. Bees work all season long gathering nectar that is placed, drop by drop, into hexagonal cells made of beeswax. After these cells are capped, bees use the honey as food to survive the colder months, but lucky apiarists can collect extra comb to extract the honey for use in baking and cooking.

Because of the complex design of the comb, you’ll need a honey extractor. Available in electric and manual forms, honey extractors use centrifugal force to spin the honey out of the comb.

Which honey extractor you choose is determined by how much honey you are processing and whether you have access to a power source to extract it.

Electric honey extractor

Electric honey extractors are available most often in stainless steel bodies with clear lids. The lids let you see the progress of extraction and judge the speed of the spin. They can hold two to 100 frames of honey at once, depending on the size of the frames and the capacity of the extractor.

As with manual extractors, frames are placed inside the extractor with either the face of the frame or the top bar positioned to the outside of the drum. Tangential extractors — the ones with the face of the frame directed toward the walls of the extractor — can only spin one side of the comb at a time. Radial extractors are more efficient, spinning the entire comb at once.

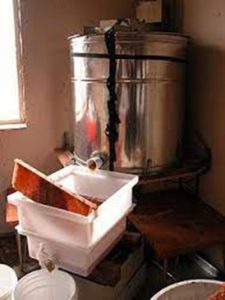

At the flip of a switch, the extractor begins to spin, forcing the honey out to the sides of the drum and down into the collection area at the bottom. A small tap at the bottom lets the beekeeper drain the collected honey into sterilized containers.

For beginning beekeepers, already awash in the start-up costs of building a few colonies of bees, an electric honey extractor may be too expensive. They range from $200-$800.

Electric honey extractor pros

Honey extractors that use electricity are remarkably easy to use. They help the beekeeper process large amounts of honey quickly — a bonus when you’re covering more than a backyard hive or two.

In addition, electric extractors can process many more frames of honey. Industrial bee operations can extract honey from 100 deep frames at a time. Considering that a full deep frame of honey weighs 8 pounds, an electric extractor makes it possible to extract 800 pounds of honey in just a few minutes. Manual extractors powered by a human just cannot handle that much weight.

Electric honey extractor cons

If you are keeping 10 or fewer colonies, or are just starting out, you won’t need an electric extractor. In the first season, most colonies will only produce enough honey to keep themselves alive over the winter. And the following season? You’ll likely get just a few frames of honey to harvest for yourself. There is no need to invest in an elaborate extractor.

Additionally, electric extractors require a power source. While many beekeepers harvest frames and bring them back to a workshop, this may not be possible in remote areas.

Electric honey extractors are also more difficult to keep clean. They must be disassembled and hand-washed to avoid damaging the motor. And as with any machine with moving electrical parts, there is always the possibility of breakdown.

We are here to share current happenings in the bee industry. Bee Culture gathers and shares articles published by outside sources. For more information about this specific article, please visit the original publish source: Electric honey extractor vs. manual honey extractor | PAhomepage.com