Bee breeder and inventor – 100 years of apiaries and orchards

by M.E.A. McNeil

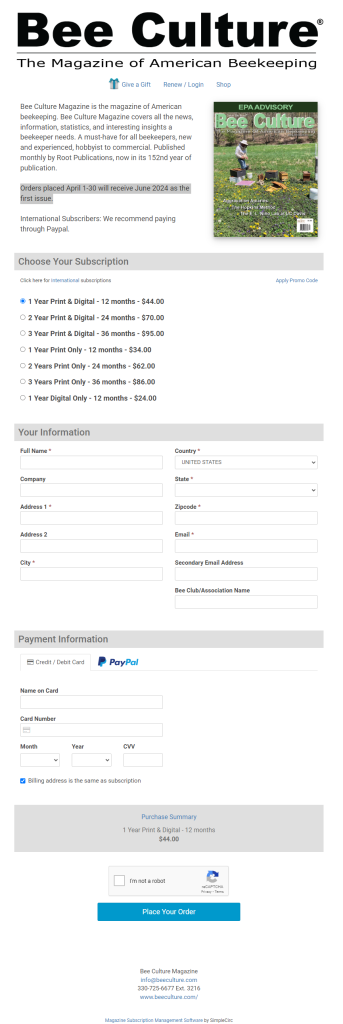

The cars rolled up California 162 and Ord Ferry Road, merging into a long, slow caravan on Highway 45 through nut tree and bee breeding country, turning in at the sign of the skep reading C.F. Koehnen and Sons. They rolled past low buildings, past orange trees laden with fruit in December, past yards of cell builders and queen boxes, past nut harvesting machinery. The envoy had come to honor the memory of Bob Koehnen. If you had known him you might have thought how pleased he would have been with the crisply straight rows that his employees waved the cars into – row after row. But for him? No, not so much; he was not a center-stage kind of guy. Nonetheless, nearly 500 people filed into a warehouse transformed for his memorial to a man who once presided here.

Presided would not be the right word for his tenure; he was, by all accounts, a man generous of spirit who did not hold himself above those he worked with. But he was a guide, a tenacious organizer – down to the minute or the last screw.

Clues to his well-lived life can be gleaned from his obituaries: He served on the board of the California State Beekeepers Association and was both a CSBA Beekeeper of the Year and Lifetime Honorary Beekeeper. He was a 50-year member of the California Bee Breeders Association and The American Beekeeping Federation. He initiated a program to reward convictions for beehive theft or vandalism and a service to alert beekeepers to pending pesticide spray applications. He loved classic cars and a collection of Harleys, on display at the memorial.

But there are values beyond those facts that have sustained a rarity – a four-generation enterprise in the same location for over 100 years. “There are a million ways for a family business to fall apart,” said Bob’s son Kalin Koehnen. He oversees their almond and walnut orchards, son Kamron the bees, and his brother Bill’s son Mike the business office and nut processing facility.

So why, if so few family farms survive, has this one flourished, drawing in each new generation? One element may be an influence of character: Cobey describes Bob as “quiet and mild-mannered. I never heard him raise his voice.” Eric Mussen, emeritus extension specialist at UC Davis, calls him “a gentleman.” Another sustaining legacy may be Bob’s principles: tenacity, respect and community.

These values remain evident within the operation. Although conflict between orchardists and beekeepers is legion, “We can tiptoe around applications and do what is most beneficial to both,” said Kalin. “There is no advantage to us to make any decisions that would be detrimental to bees. It’s kind of obvious. We treat each other the way we want to be treated, and the way we treat others.”

Bob Koehnen with his brother Bill, left to right, stand on their nut huller with the next generation in charge of their beekeeping and orchard business, Bill’s son Mike and Bob’s sons Kalin and Kameron. (photo courtesy of Yvonne Koehnen)

It’s a lesson to be heeded. Bob and later his son Kamron each tried migratory beekeeping one time for pollination, and each returned less than glad for the effects on the bees. Since then, with the exception of an isolated mountain mating yard, they have kept their bees in a 30 mile radius where there is a “gentleman’s agreement” with regard to respect for the presence of pollinators.

The family story illustrates the history of commercial beekeeping in California from 1907. Carl Fredrick Koehnen, and his brother Albert were born in San Diego to German immigrant parents. The brothers, whose catfishing business was stymied by the closure of the San Joaquin River to commercial catfishing, found a new occupation when they tasted some honey they received in trade for fish. They soon got some beehives to produce their own sweet gold, branching from Tracy to Live Oak and then further north to Ord Bend, where Carl settled.

C.F.’s venturesome spirit was matched in the young Anna Kalin, who, at 19, had migrated alone from Switzerland. They married in 1928 and that year bought 20 acres in the Sacramento Valley near Ord Bend. Then, bee forage was abundant: wildflowers grew in wide swaths and vast grain fields turned yellow with star thistle after harvest. The young couple built their home and a warehouse that is still in use at the company headquarters.

Originally, C.F. was in the bee business for honey production, packages, and queens. But honey harvests declined as open land and wheat fields were consumed by orchards with a short bloom time. C.F shifted his focus to queen breeding, sending almost all of his packages and queens to Canada, where, at that time, colonies needed to be replenished each year because they were not overwintered.

C.F. and Anna’s two sons, Bill and Bob, eventually ran Koehnen Apiaries. Bob was the younger brother; he went to Ord Grammar School and Hamilton City High School in the next town. At 16, he became a legal partner in the business, with his dad and brother, under the name still used today, Koehnen & Sons, Inc. He attended the University of California at Davis, studying pomology – although he had developed a passion for bees and skipped a semester each year to rear queens by April 1. Drafted into the Army in 1957, he saved up leave time to make it back for the queen season. “All the stories come back to getting here for grafting,” recalled Kamron.

In 1962, Bob married Yvonne Millar of nearby Glenn, who said, “I always knew there were some Koehnen boys up the road.” She, too, worked in the business as they raised their two sons – “at the heart of it with Bob,” said commercial beekeeper Pat Heitkam.

C.F., remembered by Yvonne as “a wonderful man,” died in 1978, not living to witness the disaster that struck the Northern California bee breeding market. The Canadian border was closed to bee imports in 1987, in a vain attempt to prevent the spread of tracheal mite. Many Northern California package bee and queen producers, located there to be as far north as possible to service Canada, simply folded. The Koehnens were among those that survived by turning to the domestic and international markets. They also expanded into growing nuts, which they’d grown since 1955.

The memorial for Bob Koehnen last December brought nearly 500 people together to

celebrate a life well lived. Bob’s classic truck is in the back left

corner, and his motorcycle collection was on display as well. (photo by M.E.A. mcNeil)

Bob Koehnen was known as an innovative agriculturalist. Marla Spivak of the University of Minnesota called him “inspired – unique in that he was an inventor who strove to make bee management more efficient.”

“He works it like a clock,” said Washington State University bee breeder Sue Cobey, whose first job working with bees was with Koehnens. “He didn’t veer from the routine of the system . . . There is so much detail, it can go wrong fast – just a couple of degrees in the incubator.”

He perfected an assembly-line system for making up queen-mating nuclei, synchronizing each step of an impressively large operation. Entering the premises, a visitor sees on one side of the drive dozens of hives with breeder queens, tended by Manuel Gomez. The brood boxes are sectioned off into four compartments, two of which are filled with small frames and one of the two confining the mother queen. Each frame with three day old larvae is pulled and carefully hand carried by a runner, Roberto Villalobos, to a pair of deft grafters, Josephine Rodriguez and Esmeralda Romo.

Each grafted frame holds 60 queen cells, and the accuracy of the grafters is high. The frames of new grafts are hand delivered to the other side of the drive and placed in highly populous cell starter/finishers: These are cell builders that are queenless colonies packed to swarm conditions to prompt the workers to draw out the queen cells. These colonies are continually fed syrup with top cans.

Each frame is timed to be removed from the cell builder to an incubator, and just before the queens emerge, the cells are cut apart with a unique mechanism. Then, each cell is placed into a mini-nuc queued up on a conveyor belt. The boxes are moved down the belt in an assembly line in operation every morning for three weeks. A ripe queen cell is skillfully pressed into a nuc frame, which has been lightly touched with a propane torch to melt the wax just enough for the pupating queen to be fastened to a comb. The syrup can is filled, and the conveyor belt moves the nuc through flaps covering a wall opening into a darkened room on the other side.

There, bulk bees, shaken from the yards and misted to reduce flight, are scooped into each mini-nuc with a wood-handled Spam can, which measures four ounces of bees. A third frame is added and the box is closed. The nucs are stacked six high in the cool and carefully ventilated room. The bees take up the syrup and the virgin queens soon emerge to settle in with the workers.

On the third morning, the three-day-old nucs are loaded on flatbed trucks and set out in mating yards, each with drawn comb, stored feed, a cohesive group of bees, and a newly emerged virgin queen. Once in the field, the entrance is opened, and the bees are allowed to fly. Timing starts for mating flights and for the queen to begin laying – unless there is a weather delay. When a laying queen is harvested, the mini-nuc remains in the field for another queen cell to be added.

After a day of requeening, bees cling to the pocket where Bob Koehnen was carrying queen cages. He was known as a hands-on manager, working with his crews to keep track of details. (photo courtesy of Yvonne Koehnen)

The four-man nuc crew is headed by Raul Cardenas. He arrives at 3:30 am and by 7:30 am he has fed 3000 baby nucs. The process requires an intense 95 days, seven days a week for the queen rearing season, during which 100,000 queens are produced. By June, the work winds down and the nucs are brought out of the yards to be cleaned, wrapped in plastic and stored on pallets for the next season. The entire ranch is notably orderly, a sign of the clear intention with which it is run.

The company employs workers year-round. Kalin Koehnen said of the policy, “The beauty of it is that the bees are six months out of phase with the nut harvest, so the same crew both harvests and works the bees. We rarely hire seasonal help. It takes a year to train a person, so it matters to have longtime workers.” Most have been with the company 20 years or longer, sharing a comradery that Bob valued. Josephine Rodriguez, who grafts, walked in eighth grade graduation with Kalin.

“He could have 10 employees around him visiting. The money wasn’t his main goal. He enjoyed people,” said Galen Jantzen, who worked with him in the shop. The Koehnens celebrated with their extended community at a 100-year anniversary party in 2007, that, Kalin said “eight years later people are still talking about.” At a sit-down dinner for 1200 people, they toasted their grandmother Anna, who herself was about to turn 100, as well as their late grandfather, Bob and Bill. Guests danced until the night ended with a fireworks show.

This unique forklift, designed by Bob Koehnen, has

double forks,

making it

possible to move two pallets at a time. It is one of many of his

inventions for mechanizing his operation. (photo courtesy of

Yvonne Koehnen)

For anyone who wanted to see their queen-rearing process, Bob Koehnen generously shared his expertise. Some wondered at his willingness to show his breeding operation willingly, since techniques he’d devised by trial and error could easily be copied. But Bob maintained that he had formulated his way of rearing bees and queens from the experience of many and said, “I don’t mind being a good copier.” And anyone touring their place at the height of the season could take away everything but the determined hard work, focus on detail and intuition that he imbued in every step.

“He was incredibly hard-working,” said Heitkam, who recalled seeing him running his Caterpillar, hauling hives in his truck, and shaking bees in a downpour.

Kamron Koehnen recalled, “My dad would move bees in the morning, shake bees in the daytime and graft in the afternoon, before the grafters were hired. He’d work bees all day and then spend time in the shop. I remember going on family bee moves in the evening: At six, my brother was eight, we kids would gather up the cans before my dad could pick up the pallets with the forklift.”

Cobey remembers Bob saying, “You never can stop when you get the ball rolling. You’ve got to do it now. It’s a process of detail – so many little things.” What made his system work, she said, is that he would go out with his crews, working alongside them and keeping track of minutia.

When she took a job at Koehnen, she recalled, she was just out of a beekeeping class taught by Mike Burkett at Oregon State. “It was a shock jumping into a full-scale operation – Bob was one of those special people who influenced me as a young girl wanting to learn about bees, giving me an opportunity to try things I sometimes doubted I could do” – often testing her limits. As a member of the crew, “they will go all out for you. He valued people and treated them well.” She remembers Bob showing up with oranges or cakes that Yvonne had baked.

Years later, Bob welcomed Cobey’s classes from U.C. Davis to visit. In earlier years, she had compared various queen-rearing systems with Harry Laidlaw. They found that Koehnen’s was unique because the cell builders are very strong and house different age groups, with the position of the frame signifying the age. “It’s a very good system,” she said.

Bob charted the process carefully. Spivak said, “Everyone who saw his queen rearing schedule tacked to the wall of the grafting building (which was the equivalent in complexity and organization to the Periodic Table of Elements in chemistry) knew that Bob’s management style and expectations were on a higher level, even sublime.” The chart noted subspecies of bee, position of frame of eggs pulled, grafting time and date, grafter’s name, temperature, weather conditions, number of cells, number and location of nuc, cells finished/started, feeding date and location. He was mindful of how each of these elements affected the catch.

California mini queen cages

remain a standard in the industry. Bob Koehnen developed them as well as

designing a

machine for their manufacture. (photo courtesy of Yvonne Koehnen)

Cobey notes that Bob liked to select bees for a cordovan color, a chocolate-burgandy hue that is a recessive trait found first at the Baton Rouge lab some 75 years ago. His Carniolans, which make up a third of the stock, are bred in an isolated mountain apiary with dark drones. The Italians are from queens instrumentally inseminated by Cobey.

Bob Koehnen’s fingerprints are on every aspect of the operation. For example, to increase quality and acceptance, he dipped his own queen cups from cappings wax on site. He devised an early machine to fill syrup into package feeding cans automatically.

The California mini queen cage, which remains a standard, was developed by Bob 20 years ago. He observed that queens did well without attendants inside the cage and that a smaller cage could leave frames closer together when inserted for introduction. He made prototypes on the lathe and redesigned them to his satisfaction. He found the smaller cages easier to carry in his pocket and, since more fit into a packing box, they cost less to ship.

Together with beekeeper Darrell Wenner, Bob had already developed the larger Wen-Koe queen cages. They were built with a machine, commissioned from an engineer, that adapted a technology from door construction to apply the screens.

When Galen Jantzen was hired to work in the shop in 1974, he helped Bob build out his visions. In the early 90s Jantzen built a production machine for the mini cages. Their device feeds in a long piece of wood, routs it, drills the end, and cuts it; wire screen is cut from a roll and staples are made by the machine out of wire as it shoots them in. The company has been producing queen cages for 45 years and now ships 1.25 million mini cages annually throughout the US.

Prototypes of various sizes of shipping boxes, inspired by the Rossman container, were built by Yvonne Koehnen to fit the new cages. She found that 160 small cages fit into a box that previously held 104 larger cages.

The one-inch black candy-filled tube sold with the cages was the product of experimentation to determine a length and recipe for the bees to eat through in 2½ days, which, Bob Koehnen concluded, would allow enough time for the queen’s pheromone to spread enough to make her welcome. A second-hand commercial dough mixer is used for making the candy, and the tubes are packed upright in ammo boxes, just the size to be filled 100 at a time with a machine developed by Koehnen and Jantzen. The tubes are set aside for several months for the candy to cure properly.

An ingenious mechanism for cutting queen cells apart when they come out of the cell builder was created by Bob Koehnen with Jantzen in the early 80s. Cobey calls it “unique worldwide. Everyone else does it by hand. It’s pretty impressive.” The machine cuts between 15 cells on each bar and cuts the cells off the bar before they are taken to the nuc assembly line.

Another of Bob Koehnen’s inventions is a towable bee-moving forklift with four forks, able to move four pallets of colonies at one time, then spread the pallets apart. His son Kalin said that they can move 1000 colonies a day with the double forklift.

For three months mini nucs are assembled at

Koehnen & Sons on an assembly line and then stored in this climate controlled room for three days until queens emerge. (photo courtesy of Yvonne Koehnen)

His inventions for the orchards, created with Jantzen, are many, including the development of the bankout unloading cart system for harvesting almonds and walnuts. It has a conveyer that unloads onto another vehicle without stopping, reducing time in the field.

Not every innovation was successful, Jantzen remembers, like an experimental large smoker. But, he said, “His heart was in the shop. He wanted to get his hands dirty. It was fun to work with him. He was so humble, sometimes it was like I was the boss and he was the worker. But he came up with the ideas. And he had way more ideas than we could do.”

Kalin said of his father, “No matter how bad, how tough things got, he’d always have a plan. We were always going to get through whatever. All of us, all the people who work for him, knew we were going to see the job through. I credit him with a lot of instinct that I have and the direction to go. He loved the trees, but his first love was bees. He and Bill are beekeepers at heart.”

Cobey remembers that one very rainy year Bob said that “some years are like this, and we just continue to do the best we can to stay on schedule, regardless – a simple, very wise, lesson in life.”

Kalin said that the family members running the business stay closely in touch, “keeping it real and live every day. We talk so often that communication stays open. We are three equals. We trust one another. We know that we are fortunate.” The business now includes Mike’s sons Steven and Kamron’s son Reed, the fourth generation.

Bob’s legacy to his family is apparent. But we can all learn something from this life well lived – not necessarily to emulate the specifics, for surely there are as many ways to keep bees as there are beekeepers, but to know that calm kindness, respect, inventiveness, attention to detail and hard work are fruitful, attractive attributes.

Bob Koehnen’s sons Kamron and Kalin, left to right, on either side of him, now run the family apiaries and orchards with their cousin Mike. (photo courtesy of Yvonne Koehnen)

“Bob Koehnen was an inspiration to many aspiring beekeepers,” said Heitkam. “His work ethic was unmatched. His mechanical and design ability, along with his quest for efficiency, set a high bar for the queen and package industry. Bob, together with his wife Yvonne contributed massively to our important industry.”

His son Kamron called him “the perfect ambassador.”

Contributions in honor of Bob Koehnen will be used toward the building of a beekeeping museum on the grounds of the Patrick Ranch Museum in rural Chico, and may be sent to: Bee Museum Fund – Robert Koehnen Memorial, Patrick Ranch Museum, 10381 Midway, Durham, CA, 95938.

M.E.A. McNeil is a journalist, Master Beekeeper and farmer living in California. You can reach her at: mea@onthefarm.com.