Part 6 – Getting Ready to Build

By: James Masucci

Yes! It fits! After having the sewer lines marked out and knowing I had to be at least 10 feet off them, laying down the corners helped convince me the building would fit where I wanted it. It also helped to visualize how it would lay in relation to the driveway and rest of the lot.

I’m writing about my honey house in three phases. In my last article, I bought land for my honey house. In this article, I’m going to describe how I came up with my design and what it took to get things ready to build. The first question I needed answered was whether a permit is needed. Since the answer was yes, I then needed to know what is required to comply with the building permit. Being completely ignorant, I called the county building department because the land is in unincorporated county. The big question was whether this was considered a commercial property or not, because commercial properties have more requirements. Luckily, because there will be not retail sales, meaning no customers, and few, if any employees, this qualifies for a personal storage space. Here are the main requirements for the application for a storage building/pole building/detached garage:

- Permit application form which wants to know what type of sewer, water, electricity, and gas services will be used and who will be installing them.

- A set of plans which state the depth of holes, type of material, size of lumber, and drawings of the wall sections and truss detail.

- A site plan which includes the location of existing structures and distance to property lines.

Basically, I need to know what I’m building, in detail, and where I am building it. I started by contacting a commercial beekeeper friend, John Miller, to ask him his thoughts. His first response was to ask me two questions, which everyone doing this should ask themselves. One, What is your business model? This is obvious because you need to know what you will need for your operation. The second was much more profound. What is your exit strategy? In 10-15 years when I retire from beekeeping, am I going to sell this to another beekeeper or to sell this as an improved property with a “not-too-customized” building. I chose the latter and this changed the way I thought about this. First, the primary building site I left alone so that someone can build a house there. I chose the “perfect site” for an awesome outbuilding that can be used as a shop, garage, boat storage, “man cave”, or even to put in an apartment.

I had to start thinking like a contractor. Clearing the land and pouring the foundation was not in my wheelhouse. I was able to find some good people to make it happen.

Next, I sent him a list of problems that I was trying to solve with this building and asked his advice.

Next, I sent him a list of problems that I was trying to solve with this building and asked his advice.

- I need a garage because I am getting an F450 bee truck and have no place to park it.

- I need a place to extract honey and I need an efficient honey extraction system. My garage is too small. The easier the extracting is for me, the more I will be willing to do. In the Spring and early Summer I always think I can run more bees. After extracting, I feel I have too many hives. I need to set aside room for a small, automated extraction line. That decision leads to the following questions. How big of a space? What type of flooring? What type of drainage? What do I need for clean-up? Hot water? Pressure washer?

- My kitchen is sticky for a month during honey season. I need a dedicated room for bottling. In MO, if you sell more than $50K gross in honey, you need to have an inspected facility. What do I need to pass inspection? Do I want an automated bottling system? What type of floor and drainage? What kind of washing station for jars?

- How much storage space will I need? There are honey buckets, feeders, supers, frames, boxes, sugar, water tanks, etc.

- I will need restrooms to pass the inspection for a commercial kitchen.

- What else?

I received a two page e-mail that is just full of priceless wisdom. But here are just a few of the suggestions I’ve incorporated into my design.

This is how it stands at the time this went to press. Four walls and half a roof. I will take you through the trials and tribulations of the build in the next installment.

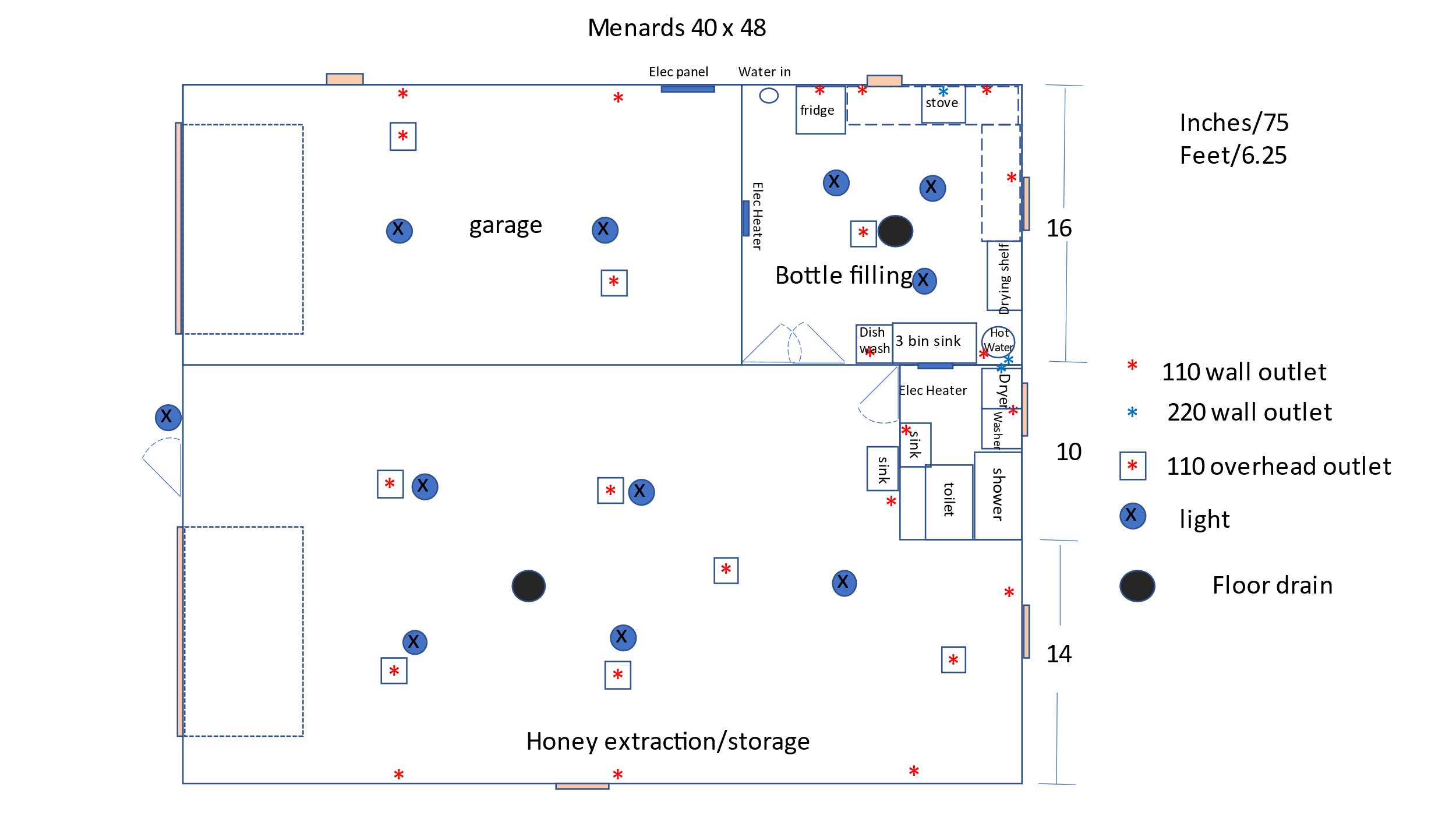

“I have never built a building too big or with too high vertical walls”. Point taken. Having a loading dock on one side (for deliveries) and walk-in elevation on the other (handicap entrance). My slightly slanted landscape makes this possible. Concrete floors that are treated every year. Smooth finish slippery and a brushed finish traps wax. Neither one is great. Have drains in the floor big enough for a thorough flush otherwise you harbor hive beetles. Make sure the floor is tapered to the drains. Have enough outlets and run electricity (and compressed air) along the ceiling because the number one OSHA violation is electric cords on wet floors. Bees get into light fixtures so get sealed fixtures that you can wash. As for the kitchen, a bottler will be nice. I will need to have a storage tank to feed the bottler and need a way to pour my honey into that bottler. I need a clear path to go from storage to the bottling tank. If I’m in barrels, I need some heavy-duty lifting equipment or a pumping strategy. If I stay in five gallon buckets, I need to have a dumping strategy. I also need a way to deal with crystallization. Lastly, based on his recommendation, I have a space set aside for a cold room. I can either fumigate my hives for wax moths or put them in cold storage during moth season.

Next, I needed to determine size and type of building. Steel buildings are the cheapest, especially with Covid lumber prices. Another commercial beekeeper, Leo Rukin, was helping me with the types of buildings. He also wants to put up a new honey house and was also looking at steel buildings. I showed him what I was looking at and he said these were all tubular designs and he was looking at I-beam designs. I asked him the difference. He figured all designs would work; the biggest difference is how much weight you can hang from the “rafters”. For him, who may have lifts to raise heavy pieces of equipment, I-beam makes sense. For me, the cheaper, tubular or pole-barn designs make sense.

Then deciding on a size. I was originally thinking 30×50 but the “I’ve never built a building too big” mantra kept haunting me. Perhaps 40×60? While visiting our parents, my wife and I stayed at an air B&B. What luck. Right on the grounds were two outbuilding and based on my pacing, one was 30×50 and the other 40×60. If it weren’t for my truck needing a really big space (say 16×32), the 30×50 would have been plenty. But, I decided then to go bigger…until I got a quote from a local contractor of $116K to put up a 40×60 building. That did not include windows, doors, electricity, and sewer hook-up. Holy cow, what did I get myself into.

I finally settled on a 40×48 building. It allows ample space for a garage, bottling room, washroom, and extraction room. The space between the bathroom and the lower wall is where I will eventually put in a cold room. That leaves a 24×40 space for extraction and storage.

It was time to get serious and determine exactly what I needed and how much I could do myself. I was looking at buildings and developing floor plans at the same time. I was at a friend’s house and their bathroom had a shower, toilet, sink, washer and dryer in a 10×7 room. Perfect! I stole the design. I figured I needed a 16×32 space for my truck. It could be smaller, but I’d rather have extra room than being too tight. Then, I figured a 16×16 space for my kitchen/bottling area. Again, possible to go smaller, but this allows me to expand into it and store jars there. This got me to a 40×48 building. If price dictated, I could fit it into a 30×48 building, but the extra space will be utilized, I’m sure. I checked at my preferred building site, and it fits.

While looking at building designs, I found a tubular design that would allow me to install the building myself (and some friends). That made me feel better because I can save money doing that. Then, I spoke with some people that put up buildings they bought from Menards. It’s a wood frame pole building with trusses. I went online, used their design tool, and voila. $21K with 11% off I get it for $19K. This includes two garage doors, one regular door and six windows (see below). That, I can afford. The trusses scare me, but I have several strategies to put them up. That’s coming in the next article (I hope).

At this point, I had to stop thinking like a beekeeper and start thinking like a contractor. I needed someone to pour the slab. Turns out there are seven to eight different ways of pouring the foundation/slab and I got quotes ranging from $23K to $47K. I need water coming in from the well. I need electricity coming from the pole. I need sewer lines and drain lines set up before the concrete is poured. This is the stuff that I know nothing about. It took several phone calls to businesses that folks recommended to me and several meetings at the building site. It was/is a steep learning curve, but finally people are lined up and the plan is in place. The building permit application was submitted last week. Wish me luck. I will let you know how the construction goes.

Click here to go directly to Part 5 – A Place for My Honey House