By: Ann Harman

Never again! The club’s two-frame, hand-cranked extractor was just fine a few years ago for Robert’s two hives but this year with five hives in a bumper-crop year extracting the honey crop was an all-night project. His helper friends slowly left through the evening. Well, you can’t blame them. Could the extraction have been spread over several evenings? Not in small hive beetle territory! He could lose some of that harvest. It is very sad to see results of the bees’ hard work all slimy and fermenting. Besides, someone else in the club had reserved the extractor for Sunday afternoon.

It is now time to consider a new extractor, one that will be useful for the next several years since he plans to expand up to about 15 hives. That will take three or four years but now is the time to see what is available for a 15-hive operation and have it in place and ready for the next extraction time next year. Not every year will be a bumper-crop year but that sort of year is when you really need a good motor-driven extractor that will accommodate the quantity of honey produced.

All the honey supers are 10-frame medium depth. This year, good weather and profuse blooms meant that each of the five hives had three mediums completely filled. That meant 30 frames of a wonderful wildflower mixture. So at 30 frames per hive times five hives – no wonder it took ‘forever.’ That’s 150 frames! Last year was a poor honey crop year – too much rain at blossom time so those five hives only filled about 50 frames.

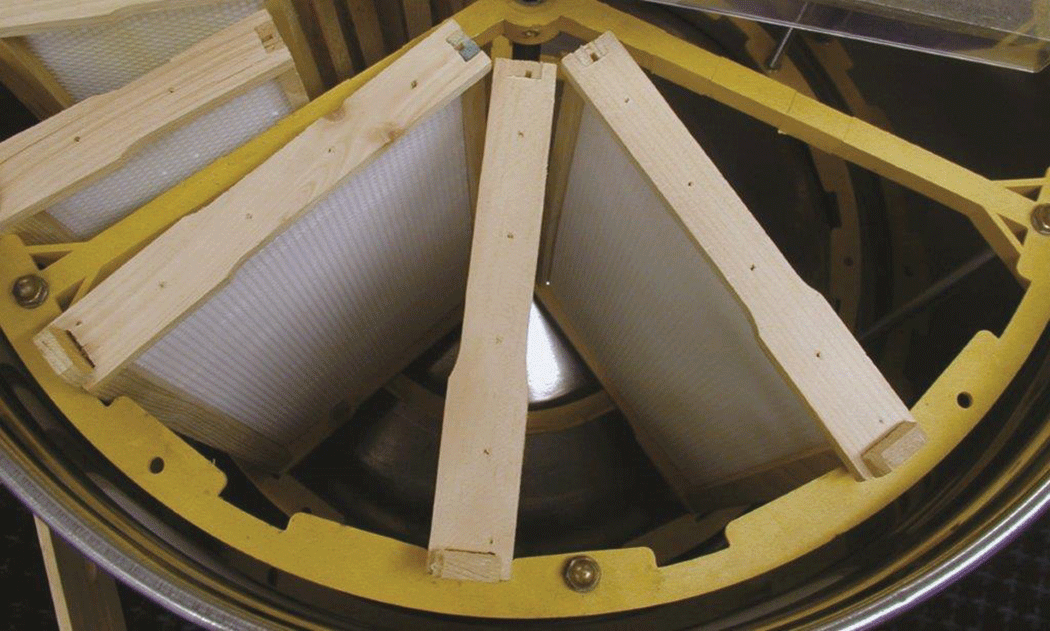

Jump forward three or four years to the goal of 15 hives. Poor year could be about 150 frames. (That is still an all-nighter with an extractor that takes only a few frames.) Bumper year – 450 frames! It is time to select an extractor. It will be motor-driven! And those big ones are radial so no need to reverse frames as in a tangential.

First let’s take a look on the Internet to see if there is anything about big extractors. Well, just putting in ‘honey extractors’ there’s not really much of interest. Chit-chat about hand-driven ones, small ones, lots of comments from really small-scale beekeepers. Maxant and Dadant seem to be mentioned quite a bit. But there are other equipment suppliers, such as Mann Lake, Brushy Mountain. Kelley Beekeeping, Betterbee and Blue Sky. True, there are many local beekeeping suppliers but their large extractors, if they actually sell them, come from some of the few manufacturers.

One of the costs of a big extractor is going to be shipping –call it ‘freight’ because a big heavy extractor, packed for travel, is going to come in a big truck. The distance from the supplier determines the cost. Kelley just has one outlet, in Clarkson, KY. Betterbee is in New York and Blue Sky is in Ohio. Cowen is in California, and Maxant is in Massachusetts. Brushy Mountain has the main shop in North Carolina, but branches in Pennsylvania and Oregon. Mann Lake has four locations, Minnesota, California, Pennsylvania and Texas, and two additional pickup locations in California. However, a peek into that catalog shows ‘Free Shipping Even on Extractors.’ That could be helpful in comparing costs. Dadant has eleven locations across the country. It may be best to determine freight after an extractor has been selected.

It is going to be easier to work from a collection of catalogs rather than online. The catalogs can be spread out on a table. The Internet, or even the telephone, can be reserved for asking questions. Since the extractor purchase can be done any time before next honey season, it might be a good idea to attend some big meetings where bee equipment company representatives will be present. It’s time to see when some state meetings will be held, and where. The three regional associations, EAS, HAS and WAS hold their meeting during the Summer. In addition, in January 2017 the two national meetings will be a joint one. Sometimes big extractors are on display. Meetings of all sizes are attended by both beekeepers and suppliers with all sizes of operations. So meetings are a great place to ask questions. Well, some information will be useful. Some will be contradictory. Go ahead and ask anyway.

Now the catalogs are spread out on the table. A pad of paper and a pencil are handy to jot down some questions.

One question comes immediately to mind. Where are these extractors made? One has to keep in mind the quotation by Russell Baker: ‘The goal of all inanimate objects is to resist man and ultimately defeat him.’ Extractors have motors and moving parts in addition to various types of electronic controls. What if something fails during an extraction? Will replacement parts be available quickly or will they have to be ordered from another country, leading to a long wait? Maxant, Dadant and Kelley extractors are made at their respective companies. So now there is a question to write down for Mann Lake and Brushy Mountain – are replacement parts readily available? The same question needs to be asked to Betterbee whose extractors are made in Poland and to Blue Sky whose extractors are Italian.

Oh look! Brushy Mountain catalog has a chart showing how much time it takes for various sizes of extractors. The time is for actually extracting, not loading or unloading the frames. However, it is a useful guide to selecting the right size extractor. A good approximation for a 15-hive operation would be a time between about three to almost five hours, depending on how many frames the extractor holds. That is certainly better than all night!

Maybe it’s time to take a look at ‘how many frames?’ Maxant’s website shows only one large extractor for 20 frames. Cowen’s are really big. Dadant has a 20-frame but the next sizes jump to 60 and 84 frames. The last two would be too big for a 15-hive operation. Kelley has a 20-frame, a 33-frame and a 72-frame. The 33-frame could be considered but the 72-frame is too large. Brushy Mountain has an 18-frame, a 21-frame and a 27-frame. The 18-frame has a German motor; the 21- and 27-frame extractors have ‘an Italian motor and a programmable controller.’ It might be a good idea to ask some beekeepers about the motors and electronic controls and ask Brushy Mountain about availability of parts. Mann Lake has an 18-frame and a 48-frame. The Mann Lake Commercial Horizontal extractor looks interesting. However it only comes in 40- or 80-frame sizes. Betterbee has two 20-frame extractors, one of those labeled ‘premium.’ Blue Sky has am extractor that holds 28 medium frames.

After looking into the sizes offered it would seem that an 18- or 20-frame would be the best size.

According to the time chart the actual extraction with those sizes would be between four to almost five hours. That is acceptable. Now to look at some other aspects of extractors in this size range.

The placement of motors on extractors certainly varies. Some are direct drive, either on top or on the bottom. Some have motors mounted on the side. Some have electronic controls; some are manually adjusted for speed. Whew! Perhaps it will be useful to ask some beekeepers about the placement and controls. Their answers will be interesting, and varied, perhaps useful and confusing, too.

Most of the gates are on the side, but a few are at the side of the bottom. Some have nylon gates and some can take metal valves or gates. Most of the extractors in the 18- and 20-frame range have legs except Dadant’s, which has a three-leg stand with the legs straight. The legs do stick outward on all the rest. It could be possible to trip over them. There’s something else to ask beekeepers about. Mann Lake shows that the legs are pre-drilled for mounting. Perhaps some of the other extractor legs are also drilled. Jot that question down.

The stainless steel bodies range from 20-gauge to 26-gauge. All the extractors with legs have the legs running up the full height of the tank so that the legs give stability to the tank. Perhaps the actual gauge is not that important. Well, put that down as a question for beekeepers.

The amount of money in purchase plus freight probably will be roughly $1500 to somewhat over $2000. Such a purchase needs to be carefully considered. It could be very useful to actually see the extractors in a beekeeping operation. Now is the time to start searching for some beekeepers to visit, even if it means a weekend trip out-of-town. Also it is time to contact some state meetings to see what vendors will be attending. The two national associations now have information online about their joint meeting so that can be put into planning. There is no point into rushing to buy something that will be used for years, even if only once or twice a year. There is a possibility of letting local beekeepers use it for their yearly extraction, provided no conflict exists with times of use.

When the extractor has been selected it might be useful to consider a settling tank. Tripping over numerous five-gallon buckets full of honey is just going to slow the processing down. Wait a minute. This is putting the cart before the horse. All those frames need to be uncapped. Then they go in the extractor. Then the honey goes into a settling tank. Now this extractor project looks like it is bigger than it appeared at first. Back to the catalogs.

Perhaps it is time to sit down and design this 15-hive honey house, start to finish. A visit to some beekeepers with this size operation would be useful. That visit could help to determine the good and the bad. The useful and the annoyance. The ease of harvesting and the wish to pack it all up and take up photography instead of beekeeping. No, it’s time to have a really great honey house. There is a book out there on the subject to look at for ideas.

Maybe those helper friends will come back after all.

Ann Harman knows all about beekeeping, honey and extractors. She lives in Flint Hill, Virginia.